Getting to Know Paderson Kinetixx

Here at THP we are always looking to expand the horizons of not just our readership, but of ourselves as well. In recent times our work with Club Champion lead us to take notice of the presence of a shaft brand that many have likely heard of, but might not truly know all that much about, that brand is Paderson Shafts.

Paderson has made a name for itself in the industry through the different materials that have applied (take Kevlar for instance) but also for their recent prevalence and success in the world of Long Drive. One thing is certain, this is not a fly by night company, rather it is one with multiple decades in the industry and manufacturing techniques, capabilities, materials, and facilities that practically no other shaft manufacturer does.

So, what better way to really learn more about a brand than to go directly to the source? Fortunately, at THP, that is always our first stop for bringing our readers the best and most accurate information. In this case, we were able to engage in some Q&A with Paderson Shafts CEO and CTO, Jason Horodezky:

THP: While you’ve been around the industry for a while now, there is a segment out there who might have heard the name or seen the shafts, but don’t truly know anything about Paderson as a company. How would you describe yourselves to those people?

Paderson: Industry patriarch and Technology innovator. Transparent and dedicated to delivering without bias an incomparable performance technical value proposition.

Our vast array of composite product technologies have set countless milestones in manufacturing, structural design geometry and MOI tuning. Although our shafts aren’t anywhere close to being the most expensive to purchase at retail, there is nothing more expensive when measured by cost of raw materials and method of manufacture.

THP: What sets Paderson apart from other shaft designers and manufacturers?

Paderson: Our manufacturing processes afford us 3° freedom, which allows us to design and deliver the most precisely tailored and disruptive technology in the market today.

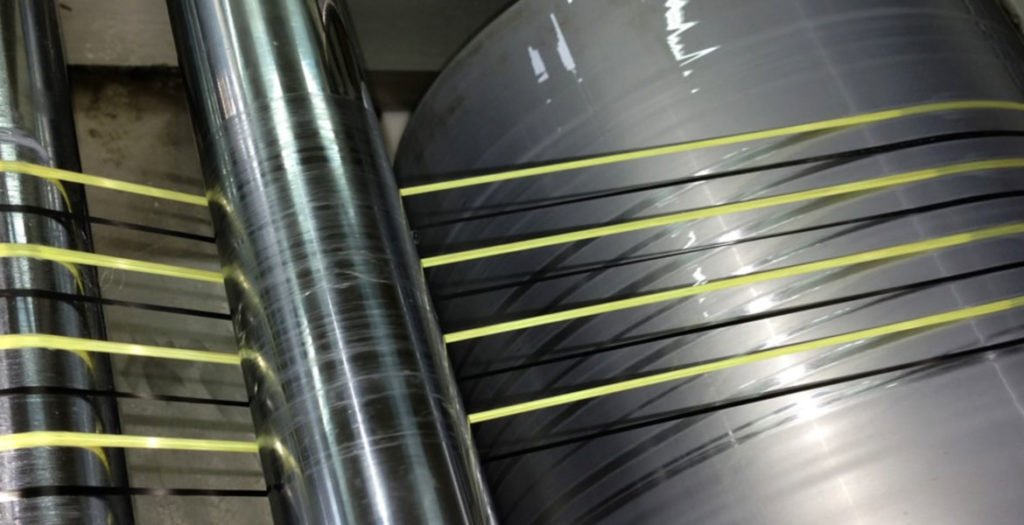

We are foremost leader in filament wound and braided shaft construction. This is evidenced in our geometrically spineless BALLISTIC, LAUNCH, Trajectory and now TUNED putter Series product lines. All of which are also produced as net parts. In other words, these shafts do not go through a center-less grinder after the curing phase to ensure roundness about the Outer Diameter. That’s unheralded in its own right, as compared to the industry and more importantly all other filament wound producers.

We are the leader in modally tuned elastically tailored MOI shaft design. Delivering the most active shafts with the highest balance points available! We also continue to put to practice materials others fail miserably with or are unable to optimize altogether, in doing so.

Take for example our use of Kevlar. We optimize the extraordinary advanced composite material properties producing shafts with an incredibly high tensile strength-to-weight ratio, 5-times stronger than steel, with 20-times the elastic strength. Kevlar has no modulus and its very dense, yet in all other applications in products that have perhaps seen greater market reception for reasoning unrelated to product, the material contribution is at best low order damping and mass location.

As a wholly owned independent global entity now 32 years in business and the world’s only “Green” composite manufacturer our >3million unit annual production capacity positions us unequivocally as the most capable “designers” and manufacturers in the space.

Finally, we are one of only two golf shaft companies who produce and sell raw materials to fabricators around the globe for use in product categories other than golf so we can speak from position of authenticity and authority.

THP: You actually own your own shaft production facility, something very few can say, what advantage does this afford you all within the industry?

Paderson: Yes, 100% of our R&D and manufacturing is organic and this places us in great company on a very short peer list, but most importantly, affords us opportunity to spare no expense to ensure we deliver an incomparable technical value proposition.

In this disproportionately overcrowded category segment, we are not like the countless marketing machines who’ve built great brands around fancy paint and decals or buying agents and former sales staff from other companies leveraging prior relationships and posing as “shaft manufacturer’s” to broker what’s unjustifiably overpriced color variations of product permutation’s, already in circulation.

The pendulum has swung from being favorable to have others hire us to build and deliver their dreams to where it is now upon us to build and deliver our own dreams to the consumer.

THP: One of the big traits of your shafts come back to combining wound and rolled shaft production along with a vacuum curing process. There is a lot to try and digest there, how would you break it down for our readers?

Paderson: Every process has boundary limits. Having the ability and seasoned practice of combining these processes, extends our boundary conditions which lends authority in addressing performance determinants that make up the finished product. From design geometry and material selection to price and position of the finished product in the marketplace. This benefits our consumer immensely.

THP: Among the biggest talking points someone sees when researching Paderson golf shafts is that you believe your designs to be the only golf shafts capable of generating and actuating kinetic energy. Just what does this mean in terms of potential performance compared to other options on the market?

Paderson: We have engineered the worlds most advanced elastically tailored composite shaft product technology. Our array of Kinetixx loaded shaft technologies are preordained to deliver the purest kinetic energy transfer in a passive (non-battery powered) system.

We need only call to waiver our ultra-forgiving utility patented VELOCITY series and its use in the sport of Long Drive. This series has now set six (6) world records for ball speed, that’s with more than just one athlete and also independent of clubhead. Producing the longest and straightest shots ever recorded in golf!

As evidenced by the 2019 Male and Female world long drive championship winning drivers. We are extremely proud of the fact Kyle Berkshire and Chloe Garner both gamed the same shaft, of identical spec to win their respective world Championship titles. This is a first in the history of the sport. What’s more impressive is the fact they are gaming a shaft flex many golfers would benefit from by a proportionately greater degree. Most importantly, all of our technology is tailored to enable golfers of all caliber to achieve a down range performance benefit. Disruptive technology that is seen and felt!

THP: If there is one thing you want golfers to know about your products, what would that be?

Paderson: Although one shaft doesn’t fit all golfers. One of our three patented and revolutionary shaft technologies will fit every golfer’s swing!

As you can see, there is much more than meets the eye when it comes to Paderson Shafts. I might even venture to say that it’s a bit mind blowing just what they are capable of doing and how they are able to do it. It also makes one realize that perhaps marketing overshadows sheer engineering at times, and there are companies like Paderson out there which have the unique ability to tune all that out and go about their business in creating products with the sole purpose of improving golfers games.

A whole lot of food for thought here, and hopefully this is just the beginning with Paderson and THP in terms of getting more info out there to everyone.

What do you think? Be sure to jump in and comment below as well as on the THP forum, there is much discussion to be had!

Especially for a self proclaimed "old guy". ?

Oh this excites me…

This makes me very very excited

Outstanding!

Sent from my iPhone using Tapatalk

I wouldn’t.

I sent an email to Paderson asking about options compared to what I am playing now and the last couple of sets, most curious as to what flex /weight they recommend since I am not a fast swinger but fairly agressive to the ball.

Are there any plans to review the iron shafts?

Paderson is the opposite of marketing spin, they actually market very very little and have their products in the best fitting studios to speak for themselves.

As for sending products, they have and are.

It would still make a lot of sense to actually get fit on a LM prior to dropping $500+ on the shafts alone. I could do the install myself, but I hate to go down the blind buying road again.

I was thinking of trying the Tungsten powder route, has anyone tried that with Graphite iron shafts? I guess the big problem is the corks to keep it in place.

Seems nuts too me without really heavy clubheads to start with.

You’re talking about the guy who once played a cobra F6+ with NO weights in it.

Also, I believe he’s playing 50g grips now

View attachment 8945817View attachment 8945818View attachment 8945819

Should be interesting to see how they play, worst case is I can swing easier and the way the back, shoulders and knees have been feeling that is a good thing.

Had some good eyes on me today and I have been yanking the club inside on the takeaway and then just shoulder swinging a shut face causing the massive pull hooks, going to have a couple of range sessions with alignment sticks and get the takeaway back to straight back and use more lower body to get back on a inside to out track…stupid game should be easy…

Yes that is what Paderson told me also, but I am buying these used and they are already Pured so it was a joke actually about it making a difference. Somebody must have bought them from CC or someone like that and they got sold the process.

Hi Jim,

IMRT technology is our patented and proprietary manufacturing process loaded into all of our LAUNCH and BALLISTIC product technology.

BALLISTIC technology succeeds our legacy series models IMRT.

BALLISTIC is an improved continuation of the IMRT line. The profiles have not been changed radically enough to replace the fitting shafts you might see in place with the more competent fitters.

We have engineered refinements into the mandrel design as compared to IMRT. But the most notable changes to the BALLISTIC series are the product of our use of the same aerospace grade resin system developed by the USA based supplier to SpaceX for the dragon capsule panels atop the falcon Rocket.

This new resin system allowed us to refine the winding pattern in all BALLISTIC and LAUNCH shafts, as well as adjust balance point and weight slightly, in each and every shaft.

Rest assured, if you were fitted off IMRT and installed BALLISTIC, you will see optimal performance.

I do not believe the Ballistic is available in the multiple colors, but it doesn’t mean they are not an option.

Email them at the address I put in the Velocity thread, tell them you are a THPer and cross your fingers.

Why? Because almost two years later this company has gone from unknown to me, to taking over my setup. The tech is real. The designs are real. Their ability to create efficient energy transfer is, by my data, for me, very real.

I’m pretty blown away.

Well worth a look. Unique is an understatement.

Me too. The fact that @Jman is such a big fan is telling. I built a wedge up once for a friend with a Paderson shaft, but have never played any myself. Very shaft curious!