Nippon Modus3 Wedge Shaft Review + A Look Into the Company

If you spend some time with a typical golfer, I bet most can quickly name at least a couple of the Nippon iron shaft product line, often the Modus3 or NS Pro lines. What many may not realize, is that Nippon produces shafts for all golfer needs, including a robust graphite selection, iron shafts, and putter shafts. As it relates to this article, I wanted to take some time to discuss the technology incorporated into the Modus3 wedge series, and how it may benefit golfers to make a change from their traditional wedge shafts.

I spent a fair bit of time researching what it means to be stamped with the “Nippon” name and I came away very impressed with their attention to detail, expectation of quality (through tolerances in the shaft), and execution. They are highly conscious of their plant surroundings in a farming valley of Japan, and respect the environment with their waste/output. The plant is at the forefront of cleanliness standards, another small hint towards their overall goal on quality and attention to detail. They have a quality control process that more than likely rivals any company out there, and scrap product that does not meet very tight expectations. With nearly sixty years of experience building and designing shafts, Nippon has a proven track record of quality.

I asked Nippon about their expectations for consistency overall tolerances from shaft to shaft, and their response went immediately to their customers and the feedback they have received.

“We’ve heard from discriminating amateurs to tour players that our shafts have the “smoothest feel” and “the industry’s tightest tolerances” by retail and corporate club builders.”

You may be thinking ‘sure, most companies have great success stories to share’ but I have to also include their actual expectation on tolerance; +/-2 grams of weight, +/-1 mm in step length, and +/- 0.1mm in diameter. That is very, very tight expectations, especially considering the product that does not meet these numbers ends up being scrapped.

Diving into the Modus3 Wedge, Nippon is going about it in a bit of a different way than some other companies. The wedge options are divided by weight rather than flex, with three options to select from. Of the three, the overall expectation would be the lighter shaft (105) would have a softer flex than the heaviest (125). When asked about this particular build logic, Nippon had the following to say about it:

The three weights gives golfers wedge shaft options to better match their irons shafts in weight and flex to achieve more uniform contact, since the MODUS³ wedge shafts are similar in weight or slightly heavier than their iron shafts’ weight. For example, if one plays a lighter weight irons shaft (100 grams or less), playing our Wedge 105 may be an easy transition since the irons and wedge shafts weigh similarly. Some golfers play heavy, firm wedge shafts – Wedge 125 may be a good match.

Seems to make a lot of sense, pairing similar weights to accommodate an easier transition, and it’s also worth considering that all Modus3 iron offerings allow golfers to play them straight down to their highest loft wedge should they prefer to do so. It makes an awful lot of sense, where many stock wedge shafts out there near that 130 gram weight range, leaving lots of golfers in a weird transition between pitching wedge and lowest loft wedge.

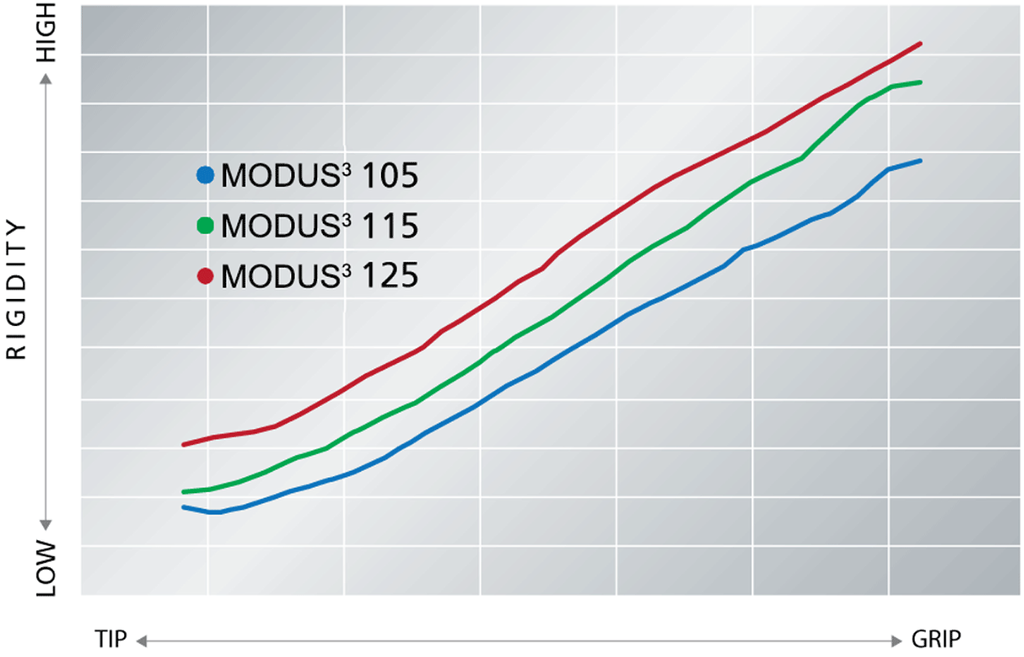

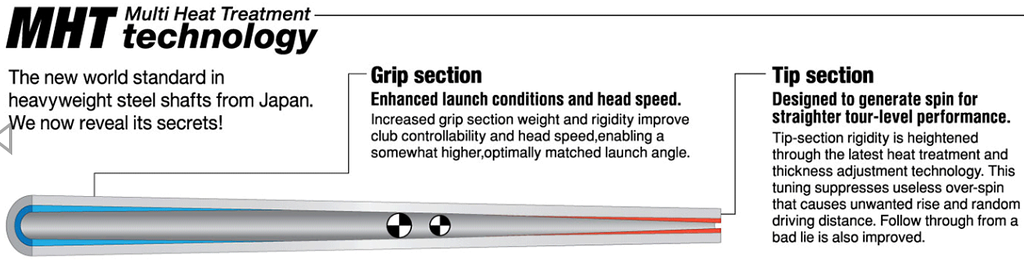

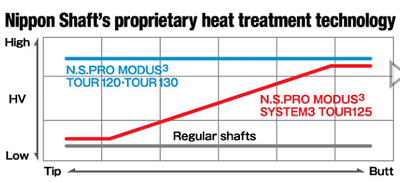

Getting ‘under the hood’ a bit with Modus3 wedge, we are looking at a fairly low torque profile overall (ranging from 1.3 to 1.6), with weights of 111, 122, and 133 grams. Each of the three profiles feature a mid kick point. They also boast a technology called MHT which is a heating process that helps them to define feeling or feedback throughout the shaft, rather than a singular profile across the entire shaft. With extra weight in the grip section of the shaft, I thought that might represent a counterbalance profile, and asked Nippon whether that was the intent, but their response was alluding to something altogether different:

“The balance points are towards the grip end, however, the MODUS³ Wedge shafts were not designed as “counter balanced” shafts. The higher balance point design will allow for more swing weight options and promote a firmer feel in the grip section.”

Spending quite a bit of time with the 115 wedge shaft profile, it is a pretty fair assessment that there is substantial stability in the overall profile, between the MHT technology and torque numbers. I never felt like I was being overpowered by the shaft stiffness, but at the same time there felt like a freedom to hit any kind of shot with the profile. Most of the time, for my game, that means a full swing at somewhere between 60-90% effort, with varying levels of drive into the ground to promote spin. The 115 wedge shafts met every challenge with ease.

Coming from a 110 gram shaft, there is about a 10-12 gram weight difference between my irons and wedges. I opted for this rather than running iron shafts through the wedges both for exploratory purposes, and because I do not mind having a bit of a profile variance between irons and wedges. What I noticed during my time with Modus3 115 wedge shafts is a pretty clear propensity to elevate the ball. Part of that is a reflection of the loft of the head, of course, but this is not a rising arc-like shape, it is just really efficient straight line rise, and a soft landing around the target area. At the end of the day, that is how I prefer to play my wedge shots, so I found great success with the profile, but that also comes with reduced action from the 100-120 yard range.

The stability of the shaft profile is not at all displeasing around the green and in the bunker. If anything, it simply maintains the head well throughout the swing and vibrates well into the hands when connection is made. I like that I can drive hard into the ground at any distance and not feel like the shaft is giving way to the turf, although I will concede that most of the testing was completed in softer fall conditions, leaving the ground softer than usual.

My overall takeaway is positive. An exciting adventure to experience Nippon’s take on wedge shaft design, and learning more about the reasoning surrounding their profile, and what technology allows them to produce said profile (see; MHT). At first glance I was skeptical about the three weight and no flex design, but then it dawned on me that in many situations, a ‘wedge flex’ replaces the traditional flex profile anyways, proving that Nippon is actually opening the door to additional fitting between the strength of additional weighting and the blend between a golfers irons and wedges. With all of these elements considered, the most impressive thing about Nippon to me may still be their extremely demanding quality control process, which could very well have them at the forefront of consistency from a shaft maker. The way they talk about tolerances and their expectations, you may as well stamp “tour” on everything they produce. For more information on the Nippon NS Pro Modus3 wedge, visit www.nipponshaft.com.

My favorite wedge shafts. Have played all 3 weights and like’em all. My info tells me Nippon has made a version for Ping – the AWT 2.0 – may flight higher than the Nippons and the weight is in the area of the Nippon 115. I love Nippon shafts. I need a Pro Modus 85 … wish they’d make them.

Great review Dan – I’ve enjoyed Nippon everytime I’ve demoed the iron shafts, I’ll definitely have to give the wedge shafts a look.

been digging the 115s I put in this summer