We've launched the new forums! Read more here

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Torched putter

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Joined

- Aug 30, 2018

- Messages

- 26,691

- Reaction score

- 22,362

- Location

- Yukon Territory, Canada

- Handicap

- 9.2

Blues look good! That is a loooooong neck!

- Thread starter

- #3

Thanks. It was a simple thing to do.. I like it. I am wondering if I can get it darker as well.Blues look good! That is a loooooong neck!

Those pictures were of Danny’s putter, been itching to try it as well. Nice job

Turned out pretty good.

- Joined

- Sep 26, 2013

- Messages

- 14,140

- Reaction score

- 11,863

- Location

- Usually on an airplane

- Handicap

- 2 Children

- Thread starter

- #7

what is the next step to improve? I kinda like the uneven look but I love how smooth yours looks as well.

Prepare an appropriate heat source, such as a charcoal fire, a propane forge, a torch, high temperature salt bath or electric furnace. Ideally, the heat source will provide a uniform heat, be easily controlled and provide a non oxidizing environment.

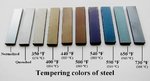

Heat the steel to temperatures from 400 to 800 degrees Fahrenheit, to produce oxidation colors. At 480 degrees F., the steel turns brown, at 520 degrees, it turns purple, at 575 degrees, it turns blue and at 800 degrees, it turns grey. These temperatures are commonly used in tempering tool steel.

Heat the steel above 800 degrees to produce incandescent colors. From 1000 to 1500 degrees, the steel will turn an increasingly brighter shade of red. At the critical eutectoid temperature of 1335 degrees, the steel recrystallizes as austenite and eventually loses its magnetic charge. From 1600 to1900 degrees, the steel will turn orange and then yellow. At 2000 degrees, the steel will be bright yellow.

Remove your steel from the heat source and quench it vertically in oil. Once the steel is cool enough to handle, temper it as soon as possible.

From sciencing.com

Heat the steel to temperatures from 400 to 800 degrees Fahrenheit, to produce oxidation colors. At 480 degrees F., the steel turns brown, at 520 degrees, it turns purple, at 575 degrees, it turns blue and at 800 degrees, it turns grey. These temperatures are commonly used in tempering tool steel.

Heat the steel above 800 degrees to produce incandescent colors. From 1000 to 1500 degrees, the steel will turn an increasingly brighter shade of red. At the critical eutectoid temperature of 1335 degrees, the steel recrystallizes as austenite and eventually loses its magnetic charge. From 1600 to1900 degrees, the steel will turn orange and then yellow. At 2000 degrees, the steel will be bright yellow.

Remove your steel from the heat source and quench it vertically in oil. Once the steel is cool enough to handle, temper it as soon as possible.

From sciencing.com

- Thread starter

- #10

They make it sound complicated. Haha. I just torched it till it turned color. Lol..Prepare an appropriate heat source, such as a charcoal fire, a propane forge, a torch, high temperature salt bath or electric furnace. Ideally, the heat source will provide a uniform heat, be easily controlled and provide a non oxidizing environment.

Heat the steel to temperatures from 400 to 800 degrees Fahrenheit, to produce oxidation colors. At 480 degrees F., the steel turns brown, at 520 degrees, it turns purple, at 575 degrees, it turns blue and at 800 degrees, it turns grey. These temperatures are commonly used in tempering tool steel.

Heat the steel above 800 degrees to produce incandescent colors. From 1000 to 1500 degrees, the steel will turn an increasingly brighter shade of red. At the critical eutectoid temperature of 1335 degrees, the steel recrystallizes as austenite and eventually loses its magnetic charge. From 1600 to1900 degrees, the steel will turn orange and then yellow. At 2000 degrees, the steel will be bright yellow.

Remove your steel from the heat source and quench it vertically in oil. Once the steel is cool enough to handle, temper it as soon as possible.

From sciencing.com

I am sure there are better ways. I didn’t pull the shaft, and did it all by hand..

- Thread starter

- #11

I like the 650 color.. will have to try and heat it again..

I just wanted you to see what colors you might expect and at what temp to get there.

- Thread starter

- #13

Totally. Thanks!I just wanted you to see what colors you might expect and at what temp to get there.

There week be variations in color and temp based on exactly what the metallurgy/make up of your steel is.I like the 650 color.. will have to try and heat it again..

If you really want to do it remove the shaft and fire up the grill. I think charcoal may get hotter than gas.

I worked for a short time with labs in Indiana and Washington state where they did this kind of stuff, also plating. And they had the biggest 3d printer and variety of materials. Really cool stuff. The navy, it's not just a job...

I worked for a short time with labs in Indiana and Washington state where they did this kind of stuff, also plating. And they had the biggest 3d printer and variety of materials. Really cool stuff. The navy, it's not just a job...

- Thread starter

- #17

How do you like the Kronos?

i like it.. I wanted a long neck putter and found this one on eBay. It feels great and has a nice weight..

- Thread starter

- #18

Well. My tinkering continued.. ended up pulling the shaft.. I may have torched it too much now but whatever..

still fun, still looks cool I think. I am also wondering if I bought a cut off wheel for my Dremmel could I beach it??

Now that it is taken apart I am looking at different putter shafts to try.. I need to get some epoxy to put it back together anyway.

still fun, still looks cool I think. I am also wondering if I bought a cut off wheel for my Dremmel could I beach it??

Now that it is taken apart I am looking at different putter shafts to try.. I need to get some epoxy to put it back together anyway.

There is a way, I think to undo some of it, and redo. Try bartenders friend for steel. Also, if your not getting the heat deep enough, it may do what you're seeing, in other words, I think you can keep applying heat. I'd start near the top of the neck and work down as you get colors you like.

Also, clean it as best you can and only handle it with gloves, or your finger prints will show.

I'm a long neck person too, until I found the 7s.

Also, clean it as best you can and only handle it with gloves, or your finger prints will show.

I'm a long neck person too, until I found the 7s.

- Joined

- Aug 16, 2020

- Messages

- 23,087

- Reaction score

- 54,616

That turned put pretty good! I was thinking about doing that to some old raw dynacraft wedges a while back. Never got around to it.

May have to give it a shot with a ping I picked up at a garage sale today

May have to give it a shot with a ping I picked up at a garage sale today

- Joined

- Feb 10, 2012

- Messages

- 54,314

- Reaction score

- 19,752

- Location

- South Georgia

- Handicap

- Cold Temps

That looks really good!

- Joined

- Sep 26, 2013

- Messages

- 14,140

- Reaction score

- 11,863

- Location

- Usually on an airplane

- Handicap

- 2 Children

what is the next step to improve? I kinda like the uneven look but I love how smooth yours looks as well.

600° part temp is your goal for a rich blue. I do it all by eye with a Map/Pro torch.

For best results, the head must be clean. And I mean CLEAN. scrub it with soap and water, degreaser, acetone, and more soap and water, and try not to touch it with your oily hands.

As you play with it you'll see that the less of a polish the more dull of a color you'll get. The best blues shine through on a mirror finish (see pics)

Here is a high buff (brushed, but still pretty shiny: )

Next up, bead blasted - fine grit

Lighter polish (notice how the color is more dull?)

Stainless is a completely different animal. My understanding is that with stainless, the color you are able to achieve has a lot to do with the amount of chromium in the metal. I've had some really nice blues in some, and others that have turned an ugly grey.

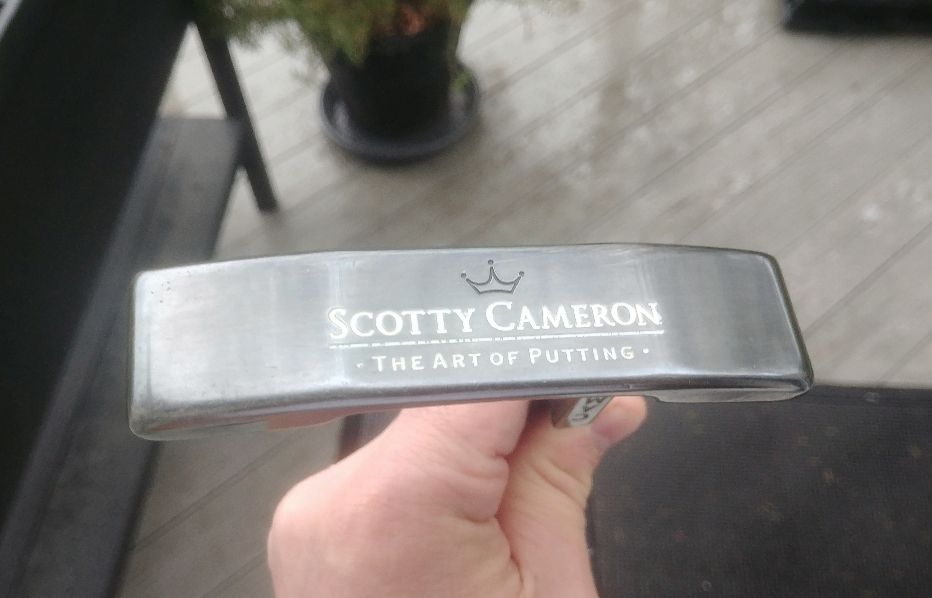

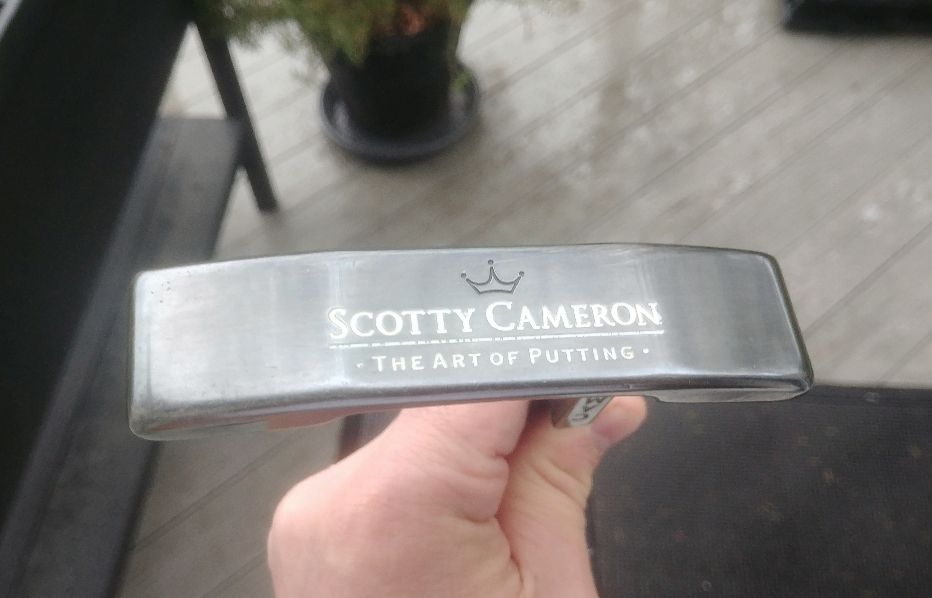

Here is what a Scotty Cameron Newport 2 oil can after I wet sanded it by hand ( sandpaper 600, then 1000 and finishing with 2000).

Then I applied gun blue and lightly polished it with 00 steel wool.

I like it!

Envoyé de mon LG-H873 en utilisant Tapatalk

Then I applied gun blue and lightly polished it with 00 steel wool.

I like it!

Envoyé de mon LG-H873 en utilisant Tapatalk

Last edited:

- Thread starter

- #24

Dang man. You have skill.600° part temp is your goal for a rich blue. I do it all by eye with a Map/Pro torch.

For best results, the head must be clean. And I mean CLEAN. scrub it with soap and water, degreaser, acetone, and more soap and water, and try not to touch it with your oily hands.

As you play with it you'll see that the less of a polish the more dull of a color you'll get. The best blues shine through on a mirror finish (see pics)

Here is a high buff (brushed, but still pretty shiny: )

View attachment 9006080

Next up, bead blasted - fine grit

View attachment 9006081

Lighter polish (notice how the color is more dull?)

View attachment 9006082

Stainless is a completely different animal. My understanding is that with stainless, the color you are able to achieve has a lot to do with the amount of chromium in the metal. I've had some really nice blues in some, and others that have turned an ugly grey.

- Staff

- #25

Love it! And love the Kronos! SO good!Motivated by seeing @Vosh68 torched M craft in the first shaft up. I tried my hand at it today.

took about 30 min and almost a full bottle of Benzomatic gas but I think it turned out pretty cool.

I may try and take to blue up the neck a bit more but I want to keep a bit of the two tone look.

View attachment 9006052View attachment 9006053View attachment 9006054