Is it as easy as starting with re-gripping?

-vice

-air compressor

-scale

Where does it go from there? club building

-shaft puller

-shaft cutting

-D balance

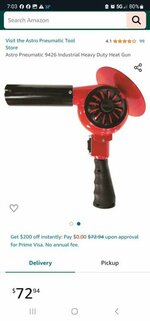

-heat & epoxy

-freq modulator

-bender

where do I begin?

-vice

-air compressor

-scale

Where does it go from there? club building

-shaft puller

-shaft cutting

-D balance

-heat & epoxy

-freq modulator

-bender

where do I begin?