Johnny mojo

Mojovated!

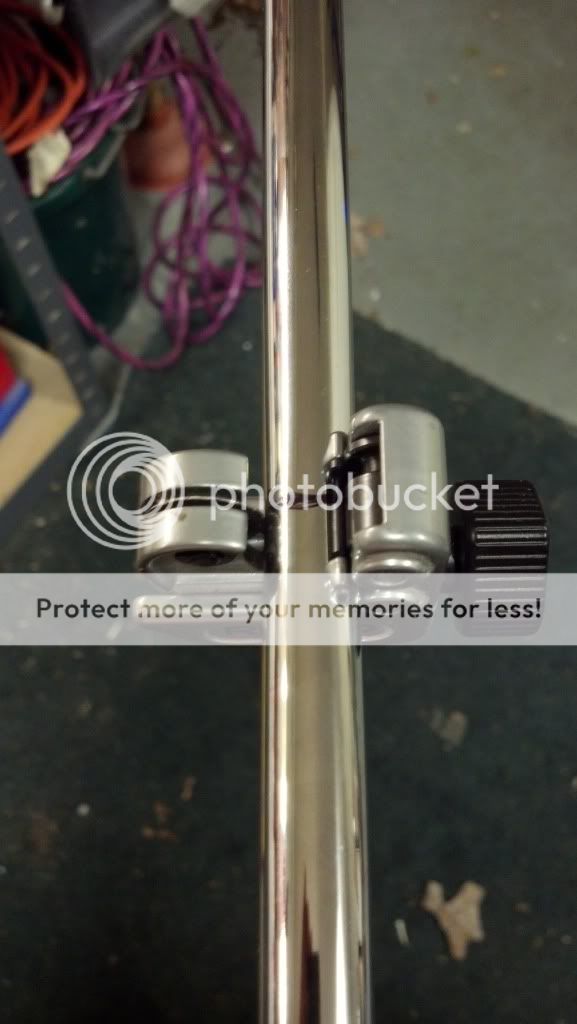

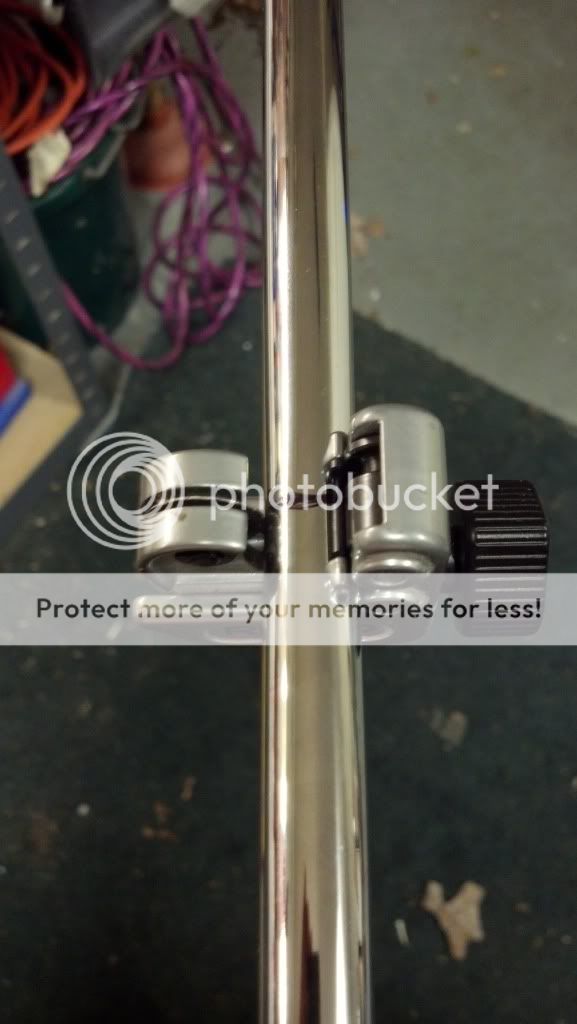

A little hand-held pipe cutter will do the trick if you have one.

Ditto, this is the one I use......from Home Depot I think

JM

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

A little hand-held pipe cutter will do the trick if you have one.

I'll try to find that, I thought I had read through all of them . Shook , did you do yours yet?The X-Hots (reg not pro), are a bore-through head. See my inquiry a few posts back. I was thinking of doing these as well.

I'll try to find that, I thought I had read through all of them . Shook , did you do yours yet?

Shook, in the golf works catalog I see they have BORE-THRU Pins and they fit in the end of the shaft for the bore thru heads and from what I can find so far it appears that you must sand and buff them to finish after installing. I'm very close to giving it a try.No, I'm pondering whether to do it at all. From the directions I've read, you'd need to get the shaft all the way in with some of it poking out the bottom of the bore hole. Then you have to grind it so its even with the sole. Then you'll need a bore-hole cap - install it and sand it down so its even with the sole. Sounds like a huge pain so that project is a ways down the road for me...

Shook, in the golf works catalog I see they have BORE-THRU Pins and they fit in the end of the shaft for the bore thru heads and from what I can find so far it appears that you must sand and buff them to finish after installing. I'm very close to giving it a try.

Question - how easily should the ferrules slide on? I'm working on one right now. Its labeled as .370 size - but there's no way it's going to fit on the shaft without pounding it or using tons of lubricant.

You have to man handle them a bit. Easiest way I have done it is get them on as far as you can, take the club head you have cleaned all the epoxy out of and then push the ferrule up the shaft to its final position. No epoxy should be used at this point, and when you get it as far with just pushing I usually tap the butt end of the club a couple more times to make sure the shaft is all the way into the club head.

You have to man handle them a bit. Easiest way I have done it is get them on as far as you can, take the club head you have cleaned all the epoxy out of and then push the ferrule up the shaft to its final position. No epoxy should be used at this point, and when you get it as far with just pushing I usually tap the butt end of the club a couple more times to make sure the shaft is all the way into the club head.

Not working either...it won't go on more than a millimeter or 2. Even tapping it down with the head. I think I was sent the wrong size...

Hmmm. You either got the wrong size sent or you ordered the wrong ones. Probably the former though. Do you still have the order sheet?

Boiling water for a very short time will do the trick in a pinch.

So I am going to mess around with my 9 iron next weekend and swap out the stock shaft for the new TT XP95 shaft and see how that plays out.

Only one question though, the stock shaft had a small 5gram weight in it that I pulled out. Do I need that weight in the new shaft or is it optional?

Boiling water for a very short time will do the trick in a pinch.

So GG forgot to trim my iron shaft, but already put the new grip on. Is there a way to get the grip off without ruining it so I can take it off, trim and put it back on?

Sent from my iPad using Tapatalk

More than likely not

I have done it. Attach the tool that is used to inflate basketballs to the compressor. Insert that needle into the hole at the top of the grip. Gently apply air pressure. The grip will need some help - it often breaks the seal on the top inch or two then I need to massage / twist the grip, which lets the air go down further. Continue until the whole grip is loose then - still using air - slide it off.Isn't there some air compressor way to get the grip off to preserve it?

Sent from my iPad using Tapatalk