- Joined

- Sep 11, 2013

- Messages

- 74,887

- Reaction score

- 88,509

- Location

- Ponte Vedra, Florida

- Handicap

- 11.9

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

Putting primer on.

View attachment 8989819

Didn't even see this one. Cabinets & cabinet doors will be pre-built. No way I want to take on that adventure.I'll say it - Measure twice, cut once. Are you going to build the cabinets or use pre built? Same question for the cabinet doors.

Didn't even see this one. Cabinets & cabinet doors will be pre-built. No way I want to take on that adventure.

In reality you’ll never really get it to match without getting out your detail brushes and adding faux grain lines along with blending the color in.Wondering if I could get a pointer or two here. Had this poplar that I used for a 'railing" and when I went to put it on the half wall I noticed it was backwards......So I hurried and flipped it over just to find out that the wood glue had already gotten to the wood. So I have these two ugly spots I have to fill. I filled them up with putty but now I'm wondering, what is the best way to stain in hopes of them not being too noticeable. I know in the long run an actual railing will need to go in but for the time being I want these spots of putty to be as hidden as possible. I'd say they are 1x2.5".

View attachment 8992496

Unfortunately this is the best picture I have. I've circled where the issue is.

View attachment 8992586

Is there an adapter that would let you tie your Festool tools into the Supercell ducting and have it work similar to how the Festool vacuum works?Two years after insulation going in I am finally getting around to drywalling. After that, my next thing is to figure out the dust collection. I always planned on putting the dust collector in the garage and then ducting it up to the woodworking shop. Right now I am torn between the Oneida supercell in the V 3000. The supercell feels like the right answer but I’ve always had my mind set that in the next dust collector I’m getting is a more traditional cyclone type like the V 3000.

View attachment 8993991View attachment 8993992

It’s definitely possible. I don’t plan on using it this way since I have 2 CT units for all my Festool stuff.Is there an adapter that would let you tie your Festool tools into the Supercell ducting and have it work similar to how the Festool vacuum works?

If that’s the use case I would decide where you want to site your collector in the garage and how you want to lay out your shop. If the supercell can provide enough cfm for your most demanding tool run I would probably go with it, just because having higher static pressure makes it a bit more versatile.It’s definitely possible. I don’t plan on using it this way since I have 2 CT units for all my Festool stuff.

The unit will go in the garage and then hard pipes up to the shop and have 6 ports with blast gates - 3 on each side of the shop.

Ever consider the Clear Vue cyclones? A lot of really good data out there by Bill Pentz regarding fine dust particulate, which I would consider giving your confined space. I'm sure you're already aware, but cfm and duct size are where you're going to get your best performance.Two years after insulation going in I am finally getting around to drywalling. After that, my next thing is to figure out the dust collection. I always planned on putting the dust collector in the garage and then ducting it up to the woodworking shop. Right now I am torn between the Oneida supercell in the V 3000. The supercell feels like the right answer but I’ve always had my mind set that in the next dust collector I’m getting is a more traditional cyclone type like the V 3000.

View attachment 8993991View attachment 8993992

I looked at them. The dust collector will be on another floor so the exhaust really doesn't matter. The supercell has such appeal because it only requires four-inch ducts and has a massive amount of CFM Along with a tiny footprint compared to a V 3000. The downside is that it starts losing performance as soon as you go above 1, 4 inch dust collection port being open. I am fairly confident that that scenario would not come up but I would be very disappointed if it did. The V 3000 is a traditional cyclone dust collector and can handle multiple tools/multiple ports being open or in use at once. The disadvantage is that it requires 6 inch ducting or larger to really get the most effectiveness out of it. The supercell just sounds like the right answer and Oneida is sad it should be the one I go with. As much as I like being on the cutting edge/bleeding edge an upgrade to a tried a true cyclone from my current single stage dust collector will be major.Ever consider the Clear Vue cyclones? A lot of really good data out there by Bill Pentz regarding fine dust particulate, which I would consider giving your confined space. I'm sure you're already aware, but cfm and duct size are where you're going to get your best performance.

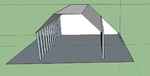

The dust collector will go in the garage and then be ducted through the garage ceiling to my shop. Here is a new 3D rendering I started to work on (not very far). So, I will have ducting running at the "crawl space" floor between the roofline and the floor (least accessable and most useless space) with 3 branches and blastgates coming up to the point just below the ceiling you see in the model.If that’s the use case I would decide where you want to site your collector in the garage and how you want to lay out your shop. If the supercell can provide enough cfm for your most demanding tool run I would probably go with it, just because having higher static pressure makes it a bit more versatile.

Correct me if I'm wrong, but isn't the max cfm of a system dictated by the diameter of the ducting? I would think that you would want to run the 6" as it allows for greater maximum flow.I looked at them. The dust collector will be on another floor so the exhaust really doesn't matter. The supercell has such appeal because it only requires four-inch ducts and has a massive amount of CFM Along with a tiny footprint compared to a V 3000. The downside is that it starts losing performance as soon as you go above 1, 4 inch dust collection port being open. I am fairly confident that that scenario would not come up but I would be very disappointed if it did. The V 3000 is a traditional cyclone dust collector and can handle multiple tools/multiple ports being open or in use at once. The disadvantage is that it requires 6 inch ducting or larger to really get the most effectiveness out of it. The supercell just sounds like the right answer and Oneida is sad it should be the one I go with. As much as I like being on the cutting edge/bleeding edge an upgrade to a tried a true cyclone from my current single stage dust collector will be major.

The Latest and Greatest Dust Collectors | Oneida Air Systems

U.S. manufacturer of cyclonic dust collection systems, components, and ductwork for personal, professional, and industrial shops.www.oneida-air.com

vs

V-System HEPA Cyclonic Dust Collection Systems | Oneida Air Systems

Our award winning V-System line of dust collectors offer the most powerful and cost-effective dust collection available for personal shops.www.oneida-air.com

That's where the supercell is a game changer. It doesn't need 6" or greater ducting. It's designed to work most efficiently with 4" ducting. I asked Oneida about it because i thought the same thing. He said to run 4", 22 gauge duct - no need to go larger. As long as I keep it under 100' of total ducting, I'm golden. That is what I'm struggling with because it goes against everything I've learned about dust collection in the last 20 years. But then again, 15 years ago, I was on the "why do I need a $700 Festool shopvac???" Now i own 2 Festool Dust extractors.Correct me if I'm wrong, but isn't the max cfm of a system dictated by the diameter of the ducting? I would think that you would want to run the 6" as it allows for greater maximum flow.

I just saw this. About the only way to disguise it is to take your sawdust and make a very thick slurry of sawdust and wood glue. Then fill with the sawdust/wood glue slurry. It's still noticeable but not as bad as just wood glue.Wondering if I could get a pointer or two here. Had this poplar that I used for a 'railing" and when I went to put it on the half wall I noticed it was backwards......So I hurried and flipped it over just to find out that the wood glue had already gotten to the wood. So I have these two ugly spots I have to fill. I filled them up with putty but now I'm wondering, what is the best way to stain in hopes of them not being too noticeable. I know in the long run an actual railing will need to go in but for the time being I want these spots of putty to be as hidden as possible. I'd say they are 1x2.5".

View attachment 8992496

And it pulls the fine particles? If so, that's a game changer.That's where the supercell is a game changer. It doesn't need 6" or greater ducting. It's designed to work most efficiently with 4" ducting. I asked Oneida about it because i thought the same thing. He said to run 4", 22 gauge duct - no need to go larger. As long as I keep it under 100' of total ducting, I'm golden. That is what I'm struggling with because it goes against everything I've learned about dust collection in the last 20 years. But then again, 15 years ago, I was on the "why do I need a $700 Festool shopvac???" Now i own 2 Festool Dust extractors.

Yep. HEPA-certified filter media - 99.97% efficiency at 0.3 microns.And it pulls the fine particles? If so, that's a game changer.

Wow, I need to do some research now. That's pretty incredible. Thanks for sharing.Yep. HEPA-certified filter media - 99.97% efficiency at 0.3 microns.

It just looks like the perfect solution for the small shop that only will use 1 tool at a time. But still (outside of cost), what is the catch? I know it's extremely noisy but with it being in another room and floor, that is not a major issue.