I want to tinker with shafts far more than I am able to because I just can't afford to pay 30-45 bucks a pop for a reshaft. I play graphite and I think golf is here to stay so I'm ready to pull the trigger and have myself some form of a club building setup but what is the bare and minimum I can get away with?

Here's what I have:

Vise w/golf shaft clamps

Heat Gun

All your basic tools, I have a sander, a drill, the little bits that you need to clean out the hosel

Swing Weight Scale

Here's what I THINK I need:

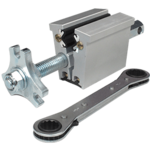

Graphite Shaft Extractor

Some form of way to regrip, but I don't really know what is TRULY needed to regrip a shaft

Is that it?

Here's what I have:

Vise w/golf shaft clamps

Heat Gun

All your basic tools, I have a sander, a drill, the little bits that you need to clean out the hosel

Swing Weight Scale

Here's what I THINK I need:

Graphite Shaft Extractor

Some form of way to regrip, but I don't really know what is TRULY needed to regrip a shaft

Is that it?