Glad I played early today can't wait to follow along.

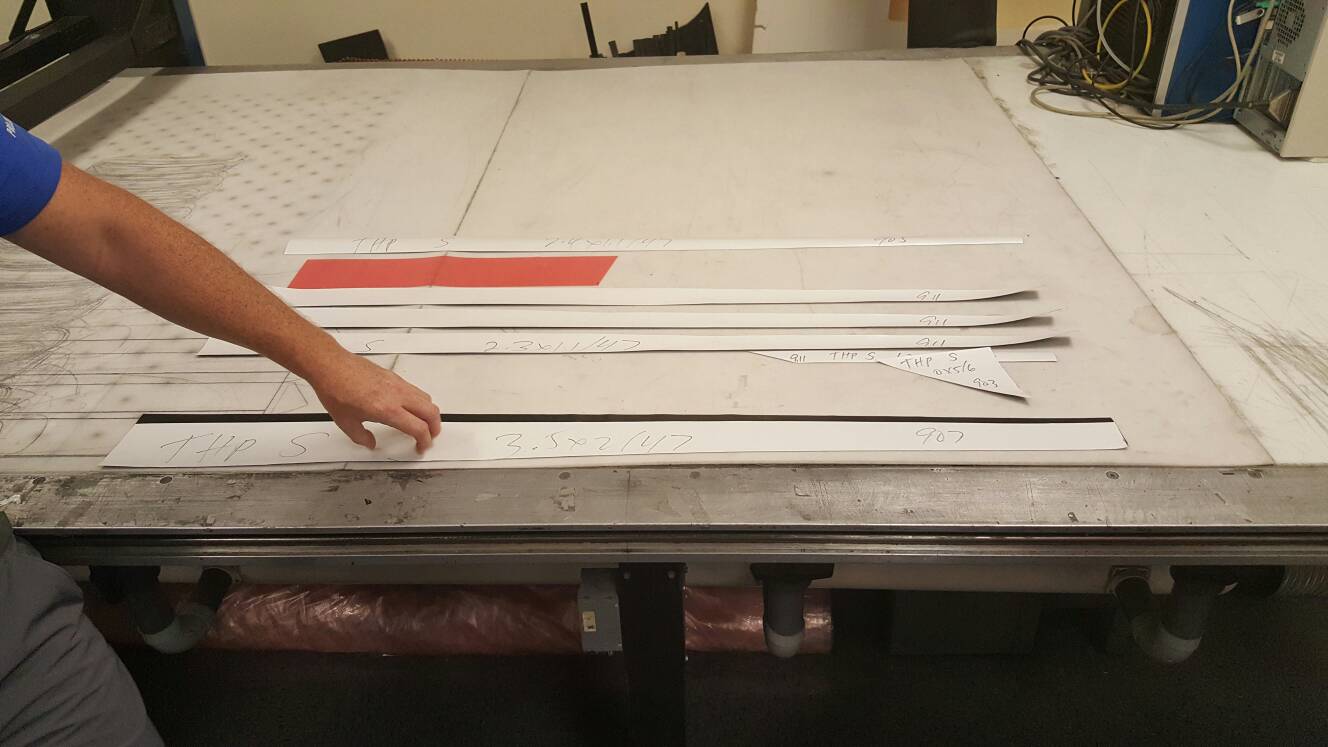

Question: For any of you previously fit in a store like I was and seeing the difference between store fittings and shaft expert fittings what is the biggest difference in the procedure to you.

Question: For any of you previously fit in a store like I was and seeing the difference between store fittings and shaft expert fittings what is the biggest difference in the procedure to you.